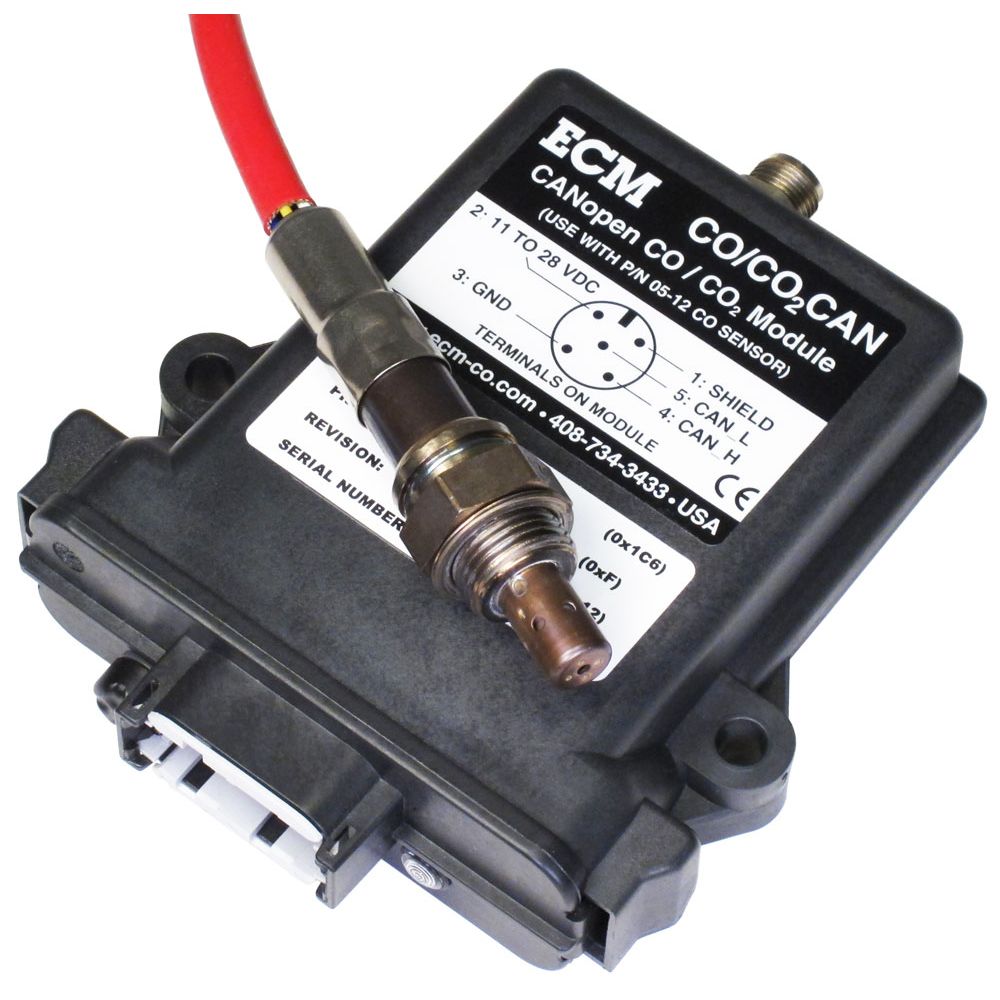

The ECM CO/CO2CAN is a versatile and highly integratable CO, CO2, AFR, Lambda, and O2 reporting device. The CO/CO2CAN uses a ceramic sensor that is mounted in the exhaust of the engine and communicates %CO, %CO2, AFR, Lambda, %O2, and all sensor parameters via its CAN port. Although designed as a measurement tool, the CO/CO2CAN can be easily integrated into an engine or aftertreatment control strategy. The CAN node identification can be programmed by the user allowing multiple modules on the same bus. Fuel H:C, O:C, and N:C ratios can be programmed. CO/CO2 sensors used with the module have memory chips in their connector where calibration information is stored. This allows the sensors to be recalibrated in a central location and distributed to users, ensuring consistent results throughout a large test facility. PC software to set-up, control, calibrate, and view outputs and sensor parameters is included (requires CAN adapter, available). For high-pressure applications, a pressure compensation kit is available. Three optional displays, two with programmable analog outputs, are available. These displays can be used with one or two modules.