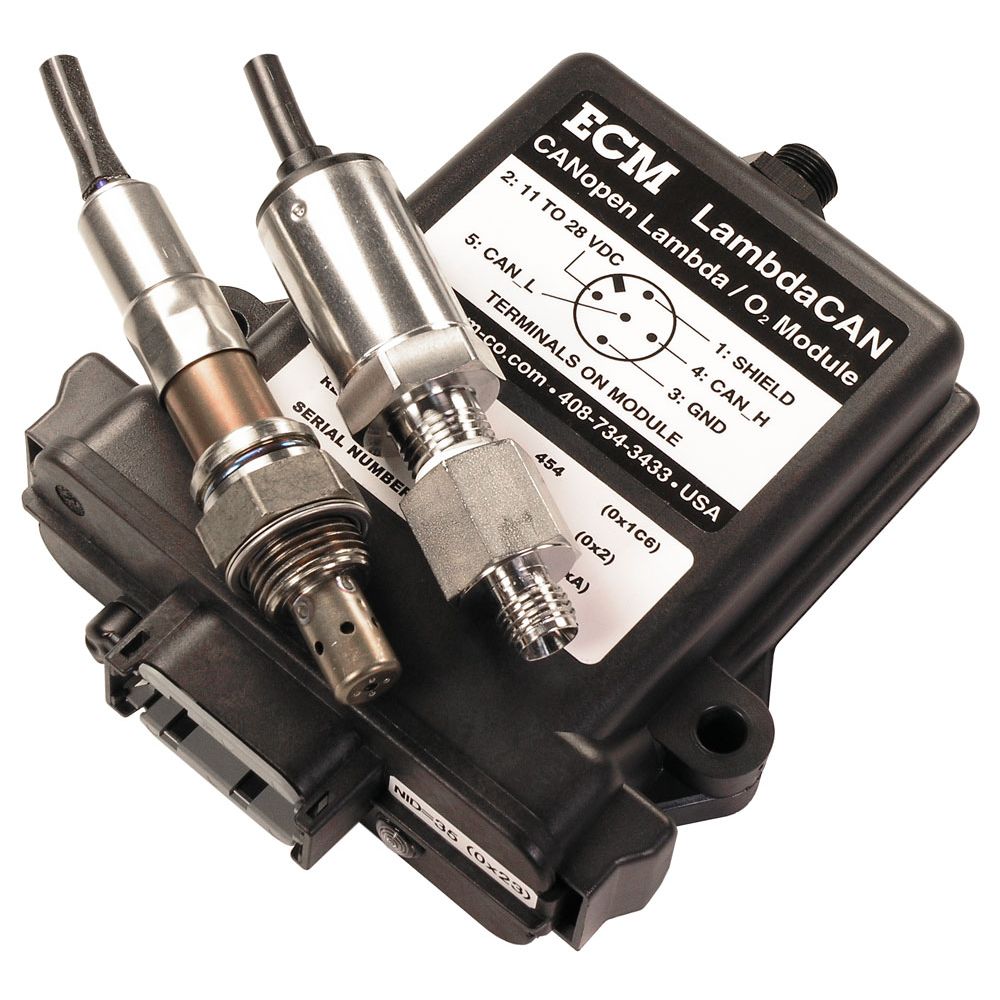

ECM’s LambdaCAN Module is a powerful, “next-generation” wideband Lambda (and AFR, O2) measurement module with a CAN interface. In addition to providing outstanding measurement range and accuracy, LambdaCAN addresses the two principle sources of error with wideband sensor use: sensor aging and pressure sensitivity. All wideband sensors supplied are factory-calibrated and this calibration is stored in a memory chip in the sensor’s connector. For best accuracy over the life of the sensor, calibration can be quickly performed using ambient air. This recalibration is stored in the memory chip and stays with the sensor. Sensors can be tested and recalibrated in a central location and distributed to users, ensuring consistent results throughout a large test facility. Pressure compensation (P-COMP™) improves accuracy at non-stoichiometric (i.e. λ ≠ 1) and non-atmospheric (i.e. P ≠ 101 kPa) conditions. For example, a pressure increase of only 34 kPa will cause an error of 0.58 λ at λ = 3. Pressure compensation eliminates this error and enables innovative applications such as %O2 measurements in intake manifolds. Pressure data is available on the CAN bus.

LambdaCAN will work with all NTK and Bosch-type wideband sensors. It is programmable for all fuel types (H:C, O:C, N:C ratios and H2). LambdaCAN outputs λ, AFR, %O2, pressure, and all sensor parameters including pumping current, resistance, and sensor age factor.